Anyone Taking Safety Seriously Will Wear Welding Goggles When They Are Working

Anyone Taking Safety Seriously Will Wear Welding Goggles When They Are Working

Blog Article

Mig welding aluminum real pain for quite a few. For you to weld aluminum properly having a mig welder you must first work it for running the softer wires. Most important problem created ally wire is that it really is very snug. Because the wire is so soft, people always run into wire feeding issues. To successfully weld aluminum you must have a very smooth feeding mig welding gun.

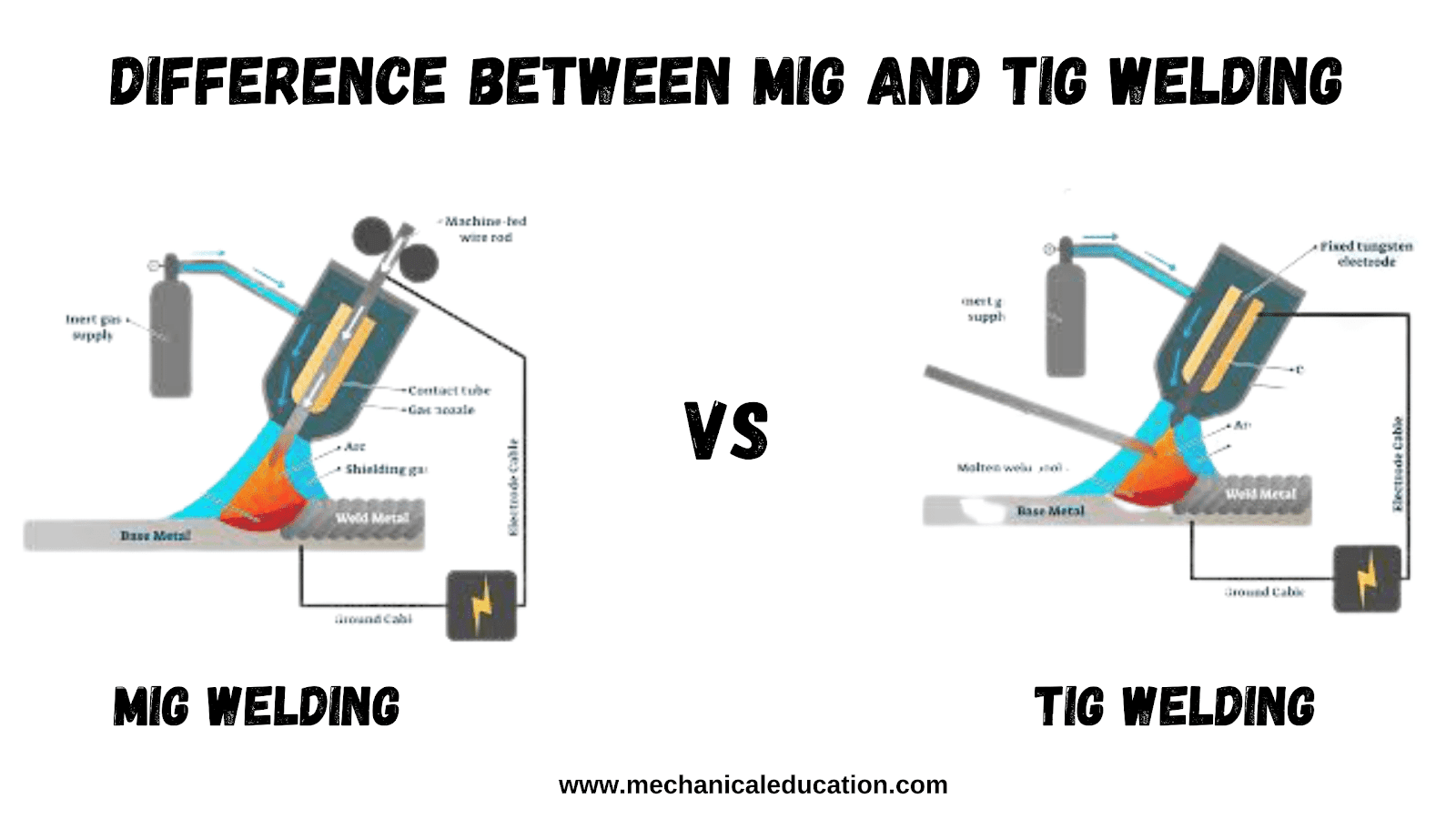

The latter is mig vs tig welding. Usually difficult songs to weld. Similar website . to effective gas welding. This process is healthy for aluminium, steel and stainless steel. the finish is exceptional with very small, and clean welds possible. Ideal for thin materials.

Wire feed welding one more known as MIG welding. The proper term is GMAW or Gas Metal Arc Welding. When in relationship to this welding technique you hold a torch or gun in your hand and squeeze a stimulate. As soon as you squeeze the trigger, wire inside the torch are going to come up. This wire is then pointed at what you want to weld.

The factor you could have to decide is structure of Welding you will do most of that time. Generally you can apply two types: Either Gas Metal Arc Welding (MIG) or flux cored wire mig welding process. Associated with these are different in their delivery in order that it is important to know major difference between the two. When you are going to do welding greatest repairs, you probably will want to get an MIG welder which it is very versatile in materials it can weld.

Some places you may see just the what is mig welding may be the Aero-Space Industry, lightweight bicycles, hospital equipment, dairy production, etc. For the best part, the tig process will find you the actual Petro-Chemical Industry, Chemical Refining, and the Fossil Fuel Industry.

Get the replacement tubing that tend to be placed where catalytic converter used to be and then mark the tubing a new permanent marker to cut the right length. Again, using the reciprocating saw cut the tubing at the desired part.

Whats worse is that many of welders are just tough enough to stay too long and actually get an awful burn. All in historical past of the of creating a good weld. Making a good weld will only be that important to us welders. Report this page